ORIOLE: OutlieRs detectIOn waLk wEighing

A web application for the automatic filtering of outliers in databases produced by the Walk-over-Weighing (WoW) platform

Loading, please wait...

References:

- To cite the WoW device, please use the following: Evaluating a Walk-over-Weighing system for the automatic monitoring of growth in postweaned Mérinos d’Arles ewe lambs under Mediterranean grazing conditions. Estelle Leroux, Irene Llach-Martinez, Gaelle Besche, J.-D. Guyonneau , Denis Montier et al. Animal - Open Space, 2023, 2, pp.100032. 10.1016/j.anopes.2022.100032.

- To cite the kfino method, please use the following e-Print by Cloez B., Fontez B., González García E. and Sanchez I. (2022): arXiv:2208.00961.

Producing daily individual liveweight data in sheep without human intervention: the necessary filtering step when using raw databases from the Walk-over-Weighing (WoW) technology

Rationale behind, origin and genesis of the WoW technology for sheep

Liveweight (LW) is indicative of an animal’s current and changing physical state and is affected by several factors such as growth or physiological status. It is one of the most conventionally and widely used parameters in livestock due to ease of collection and understanding, comparability potential for longitudinal monitoring within and between animals, changes in response to a range of stimuli, and flexibility of using quantitative data for statistical analyses and different purposes. However, irrespective of the system and despite the advantages of LW monitoring, the vast majority of farmers do not weigh their animals at all. This is mainly because of lack of time of farmers for organizing, regularly, this laborious and time-consuming, stressful task, beyond other related economic issues.

The LW is typically used for management purposes in several different ways e.g., for monitoring weight gain, body condition, animals’ health and nutritional status, responses to feeding programs, or setting slaughtering schedules. As LW is a common parameter which can be useful for farmers' decision making, the frequency of recording and analysing weighing events might change depending on the farmer's management objectives.

But, for measuring LW of one animal, the Gold Standard method is to use conventional static weighing systems, which require animals to be individually walked onto a set of scales and a measurement recorded when the system comes to equilibrium. This process is time consuming, labour intensive, and places stress on both the animals being weighed and the operator carrying out the process. Furthermore, recording individual LW outdoor may become a difficult task due to factors such as adverse weather conditions, topography or animals being scattered over a large area. As an alternative to static weighing, automatic technologies may provide a more sensitive, objective and less labour-intensive method for tracking LW change, thus allowing easier identification of animals at risk of disease or with reduced reproductive performance or improved management at the herd level (Dickinson et al., 2013). Automated weighing systems provide more information and what could be lost in the accuracy of the equipment may be regained in the number of records available for the analysis (Brown et al., 2012).

Some studies have reported however the feasibility of using walk-over-weighing (WoW) technology that provides dramatically more information than conventional static weighing scales enabling new ways to use LW in farm animal species. Providing several advantages over static methods such as higher frequency of LW measurements without stress, the WoW is a method that requires animals to pass through a specially designed crate, which allows body mass to be estimated using continuous averaging techniques (Long et al., 1991; Ren et al., 1992; Peiper et al., 1993) involving the electronic circuit averaging the fluctuating signal while the animal is crossing over a given time and, once the animal leaves the platform, then registers the average LW value. The weight averaging circuit involves integration of the incoming electrical signal from the weigher for a period of about 2.5 seconds (Smith and Turner, 1974). An example of the block diagram of a weighing circuit was reported since 1979 by Filby et al. for a WoW platform used for dairy cows at the exit race of a milking parlor.

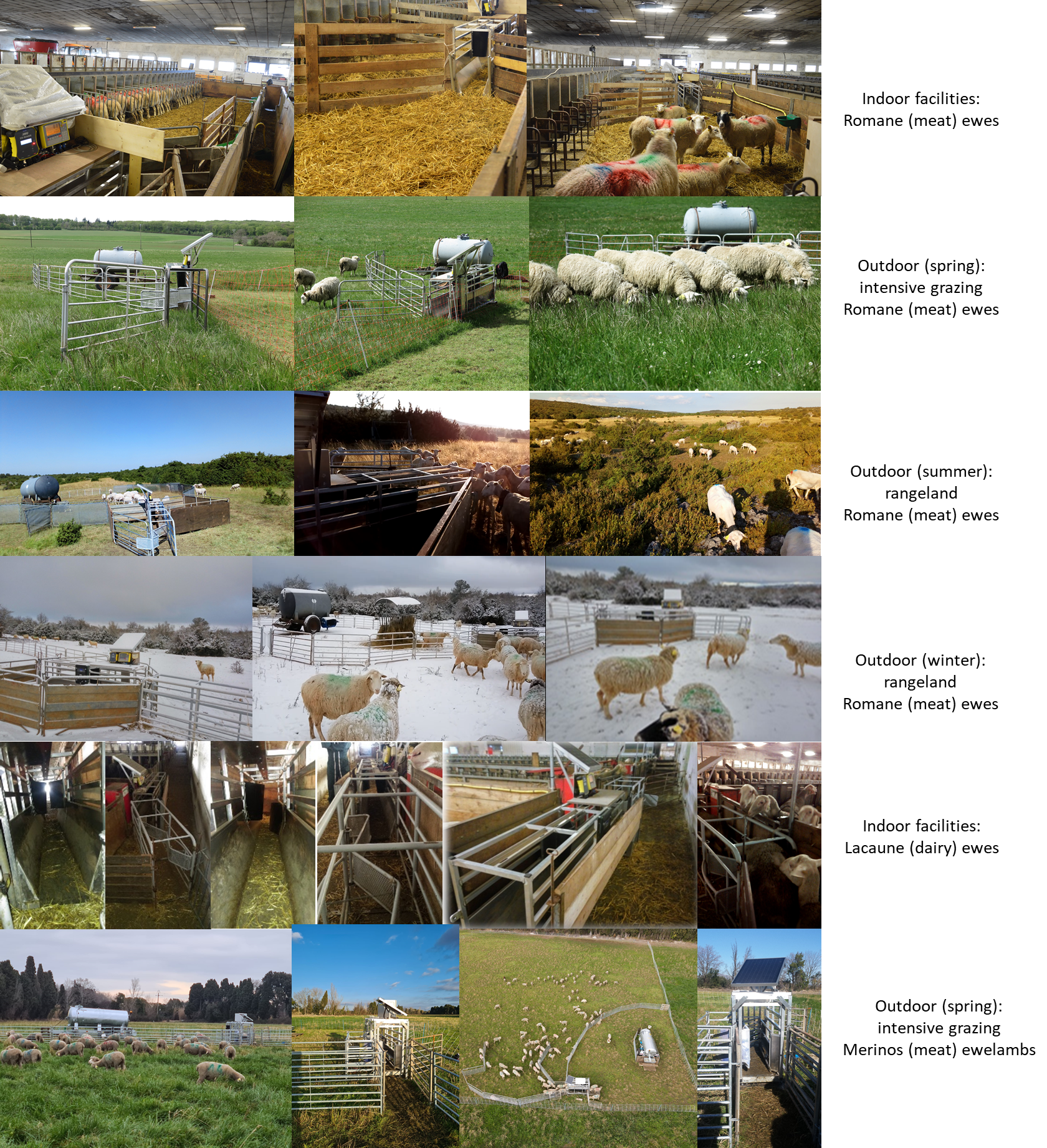

Such autoweighing technology could be used in a range of situations to help farmers, including indoor or even outdoor grazing systems. Indoor, it would enable an immediate improvement in individual monitoring of LW (without human intervention) and animal welfare conditions (with no stress linked to LW sessions). It would represent a direct contribution to the farm economy (i.e., by reducing labour and time for weighing animals). Outdoor, it would represent probably the most adapted and almost the only technology for monitoring LW frequently and easily, without human intervention, if the conditions of autonomy in energy and resistance to the external environmental conditions are warranted. In both situations, continuous access to a massive dataset of individual and daily LW data would allow farmers and advisors a better understanding of nutritional requirements, decision-making when LW gains or losses occurs, adoption of precision feeding practices (e.g., individual ration calculations), or monitoring flock health status (i.e., utility of LW monitoring from the veterinary point of view).

Design and conception of the WoW prototype in France

In ruminants, until now studies have been conducted mainly in cattle (Alawneh et al., 2011; Aldridge et al., 2017; Dickinson et al., 2013; Imaz et al., 2019; 2020; Kedzierski, 2020; Menzies et al., 2018), whereas in sheep, the only available reports before our works at INRAE were those reported by Brown in Australia (Brown et al. (2012; 2014a; 2014b).

The aim of the initial project (González-García et al., 2018a) was to trial the feasibility of using an automated weighing prototype suitable for a range of contrasting sheep farming systems (e.g., indoor and grazing outdoor in spring or winter). We hypothesized that the strategic conception and design of the WoW system would allow to register accurate LW data on individual sheep on a daily basis. The accurate WoW data would be comparable to the static or gold standard weighing method to within a defined level of tolerance. Thus, the study involved i) designing a new WoW prototype platform, original with regard to what was available in the market (Figure 1), ii) designing a device to control the flow of animals through the WoW system (Figure 2) in order to increase the accuracy of WoW data, and iii) training the ewes to traverse the WoW unit in a single direction to access attractants in a small yard. This final project was approved in the scope of a 2016 research grant of INRAE PHASE Division (Physiologie Animale et Systèmes d’Elevage) and a collaboration developed in the framework of an INRA-CSIRO (Australia) linkage program. Initial investigations were carried out at INRA Experimental Farm La Fage, Causse du Larzac (43°54′54.52N; 3°05′38.11E; ∼800m altitude), Roquefort-sur-Soulzon, Aveyron, France.

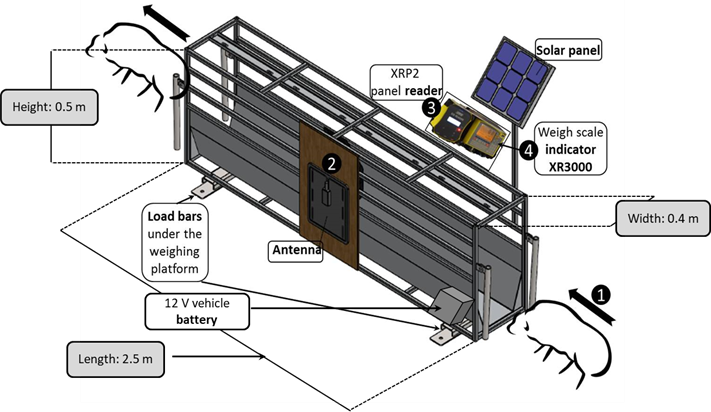

Figure 1. Illustration of the portable, mobile sheep Walk-over-Weighing (WoW) platform specifically designed for the autoweighing of sheep in a spectrum of conditions. (1) The animal enters the WoW unit voluntarily, (2) the antenna reads the animal electronic identification (ID) tag, (3) sends it to the XRP2 panel reader which records ID tags into a session file which (4) ID is sent directly to the weigh scale indicator (XR3000, XR5000 or WOW2) to record individual animal LW and other information, for example day of the experiment, hour, breed. The operator downloads the stored files with the individual LW information for further processing and interpretation.

The original prototype (Figure. 1) was conceived and designed with the objective of developing an experimental tool for carrying out projects on feed efficiency and adaptive capacities of ruminants. A fine and continuous monitoring of individual LW is often required in these projects e.g. for validating a non-invasive method for estimating individual forage intake in sheep (González-García et al., 2018b). The prototype was constructed by Marechale Pessage (Chauny, France) private society with a design taking into account key elements like energy autonomy (i.e. equipped with solar panel and a 12 V power vehicle battery), being light for easy transportation and mobility and with corrosion resistant materials (e.g. aluminium frame). The main components of this automatic WoW prototype consisted of a set of two electronic load bars which contain weight sensing load cells and a weigh scale (model MP600; Tru-Test Ltd., Auckland, New Zealand), an indicator with data logging capabilities (model XR3000 indicator; Tru-Test Ltd., Auckland, New Zealand), an RFID antenna (Allflex) and an electronic identification tag panel reader (XRP2; Tru-Test Ltd., Auckland, New Zealand). The load bars are placed beneath the platform and connect the indicator via cables. As it is mandatory in France, all the ewes were equipped with RFID ISO 11784/11785 transponders allowing permanent individual identification. The weight measured by the load cells and the RFID read by the reader panels are both sent to the indicator which calculates the weight of each animal and logs this together with the RFID, date and time. The antenna was placed in the left side of the WoW unit and connected via a serial connection cable (9 pin universal RS232 connector cable) to the indicator storage. The XR3000 or WoW2 indicator have internal rechargeable batteries that provide a running time of up to 14 h when fully charged and was installed with patented algorithms that calculate weight of a shifting object (Tru-Test Ltd., Auckland, New Zealand). The initial WoW aluminium platform weight is 97 kg and the dimensions are: length 2.5 m, width 0.45 m and height 0.90 m (Figure. 1).

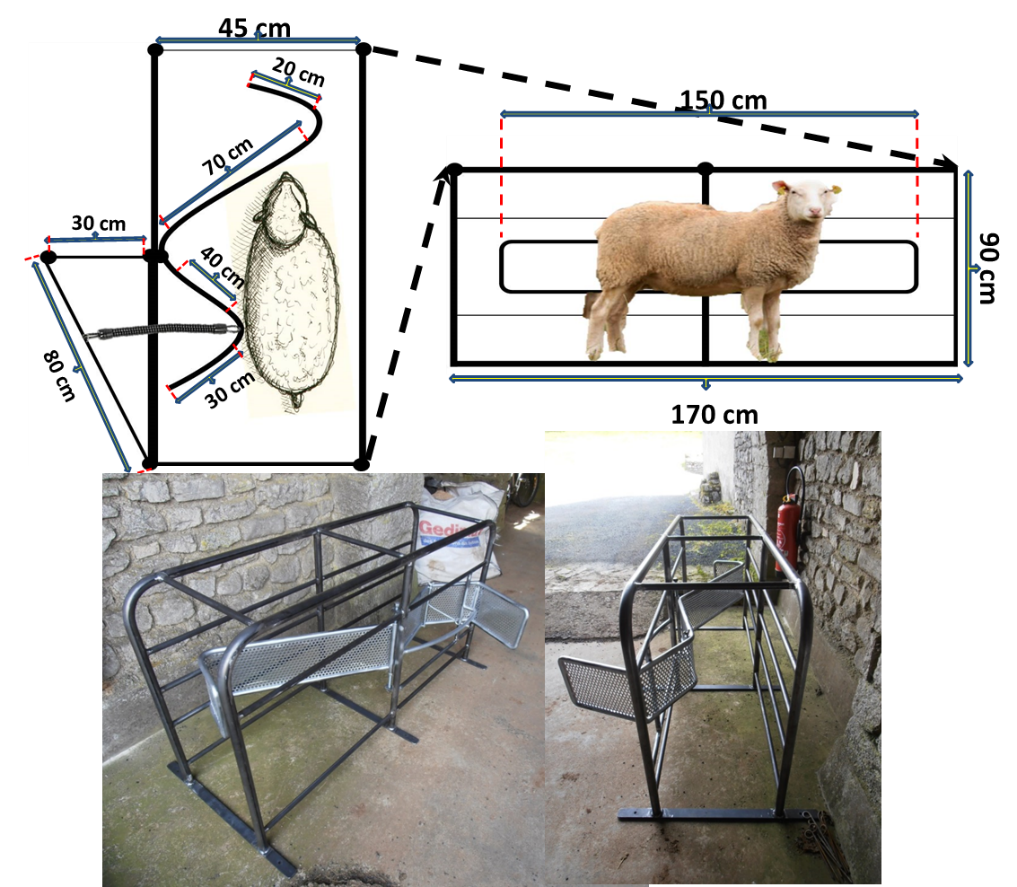

The WoW system was completed with a customized metallic structure with S shape (Figure. 2) which is placed at the entrance of the WoW platform. This structure was designed to control the flow and to force ewes to cross the platform with sufficient succession distance to prevent congestion. The height of the S structure can be adjusted to suit the frame size of sheep. In average situations, the intermediate position (0.45 m) is used to cater for the medium-framed sheep. The overall result is a light, mobile and autonomous experimental unit that can be used in a wide range of farming situations including harsh outdoor conditions (Figure. 3).

Figure 2. A customised sheep ‘flow-control’ device (a metallic structure so-called S) placed at the entrance of the WoW unit (González-García et al., 2018a).

Figure 3. The Walk-Over-Weighing (WoW) platform prototype being used in a large spectrum of sheep farming systems including indoor and outdoor intensive or extensive grazing or rangeland conditions.

The original prototype recently evolved to a more compacted one in the scope of the project OtoP_3D in collaboration with IDELE in France (Institut d'Elevage: Figure. 4).

Figure 4. The Walk-Over-Weighing (WoW) platform prototype evolved to a more compact format combining the module S inside.

However, using the WoW under real situations means the production of a lot of outliers' data. Therefore, authors agree on the high importance of carrying out relevant filtering methods on raw data in order to remove spurious LW records obtained with WoW (e.g. resulting from animal behaviour issues) and to achieve the required accuracy and repeatability of data for reliable interpretation. In our team, we traditionally use the methods of Bland and Altman (1999) and Lin et al. (1989) to evaluate precision, agreement, repeatability... The current platform or web application proposes is an automatic alternative which incorporates the recently developed kfino algorithm for addressing this complex and essential process looking to expand the use in routine of the WoW technology by a large spectrum of end-users going from the researcher, technicians, advisers or farmers.

References

- Alawneh, J.I., M.A. Stevenson, N.B. Williamson, N. Lopez-Villalobos, and T. Otley. 2011. Automatic recording of daily walkover liveweight of dairy cattle at pasture in the first 100 days in milk. Journal of Dairy Science 94:4431–4440. doi:10.3168/jds.2010-4002.

- Aldridge, M.N., S.J. Lee, J.D. Taylor, G.I. Popplewell, F.R. Job, and W.S. Pitchford. 2017. The use of walk over weigh to predict calving date in extensively managed beef herds. Animal Production Science 57:583–591. doi:10.1071/AN15172.

- Bland, J.M., and D.G. Altman. 1999. Measuring agreement in method comparison studies. Statistical Methods in Medical Research 8:135–160. doi:10.1191/096228099673819272.

- Brown, D.J., D.B. Savage, G.N. Hinch, and S.J. Semple. 2012. Mob-based walk-over weights: Similar to the average of individual static weights? Animal Production Science 52:613–618. doi:10.1071/AN11306.

- Brown, D.J., D.B. Savage, and G.N. Hinch. 2014a. Repeatability and frequency of in-paddock sheep walk-over weights: implications for individual animal management. Animal Production Science 54:207–213. doi.org/10.1071/AN12311.

- Brown, D.J., D.B. Savage, and G.N. Hinch. 2014b. Repeatability and frequency of in-paddock sheep walk-over weights: implications for flock-based management. Animal Production Science 54:582–586. doi.org/10.1071/AN12402.

- Dickinson, R.A., J.M. Morton, D.S. Beggs, G.A. Anderson, M.F. Pyman, P.D. Mansell, and C.B. Blackwood. 2013. An automated walk-over weighing system as a tool for measuring liveweight change in lactating dairy cows. Journal of Dairy Science 96:4477–4486. doi:10.3168/jds.2012-6522.

- Filby, D.E., M.J.B. Turner, and M.J. Street. 1979. A walk-through weigher for dairy cows. Journal of Agricultural Engineering Research 24:67–78.

- González-García, E., M. Alhamada, J. Pradel, S. Douls, S. Parisot, F. Bocquier, J.B. Menassol, I. Llach, and L.A. González. 2018a. A mobile and automated walk-over-weighing system for a close and remote monitoring of liveweight in sheep. Computers and Electronics in Agriculture 153:226–238. doi:10.1016/j.compag.2018.08.022.

- González-García, E., P. de O. Golini, P. Hassoun, F. Bocquier, D. Hazard, L.A. González, A.B. Ingham, G.J. Bishop-Hurley, and P.L. Greenwood. 2018b. An assessment of Walk-over-Weighing to estimate short-term individual forage intake in sheep. animal 12:1174–1181. doi:10.1017/S1751731117002609.

- González-García E., Alhamada M., H. Nascimento, D. Portes, G. Bonnafe, C. Allain, I. Llach, P. Hassoun, J. M. Gautier and S. Parisot. 2021. Measuring liveweight changes in lactating dairy ewes by using an automated walk-over-weighing system. Journal of Dairy Science 104. doi: 10.3168/jds.2020-19075.

- Imaz, J.A., S. García, and L.A. González. 2019. Real-time monitoring of self-fed supplement intake, feeding behaviour, and growth rate as affected by forage quantity and quality of rotationally grazed beef cattle. Animals 9:1129. doi:10.3390/ani9121129.

- Imaz, J.A., S. García, and L.A. González. 2020. Application of in-paddock technologies to monitor individual self-fed supplement intake and liveweight in beef cattle. Animals 10:93. doi:10.3390/ani10010093.

- Lin, L.I.-K. 1989. A Concordance Correlation Coefficient to Evaluate Reproducibility. Biometrics 45:255. doi:10.2307/2532051.

- Long, J., Takahata, H., Umetsu, K., Hoshiba, H., Takeyama, I., 1991. A livestock walkthrough scale system. J. Soc. Agric. Struct. 21, 175–182.

- Menzies, D., K.P. Patison, N.J. Corbet, and D.L. Swain. 2018. Using walk-over-weighing technology for parturition date determination in beef cattle. Animal Production Science 58:1743–1750. doi:10.1071/AN16694.

- Peiper, U.M., Edan, Y., Devir, S., Barak, M., Maltz, E., 1993. Automatic weighing of dairy cows. Journal of Agriculture Engineering Research 56, 13–24.

- Ren, J., Buck, N.L., Spahr, S.L., 1992. A dynamic weight logging system for dairy-cows. Trans. ASABE 35, 719–725.

- Smith, R.A., and M.J.B. Turner. 1974. Electronics aids for use in fatstock weighing. Journal of Agriculture Engineering Research 19:200–311.

How to use ORIOLE?

1/ Please click on WoW data to scroll down the menu

2/ Select a dataset to import. You have to import an excel file. The app is implemented to import the first sheet in the file.

The following columns are mandatory: record of the measured liveweight by the WoW, date (YY/MM/DD), hour (hh:mm:ss), id of the animal

Here, an example of the structure of the input excel data file:

3/ Give minimal and maximal liveweight values as expected for the group of animals or flock you are handling.

4/ Please, choose a method to detect outliers:

- kfino: Kalman filter with Impulse Noised Outliers (Recommended as default method)

- locfit: local regression

The kfino method is performed using the kfino package. The input parameters of the kfino method are:

5/ After tuning those parameters, click on the Launch Analysis button to execute the analysis.

6/ The results are available when clicking on the Cleaning data item in 4 tables:

- Imported data: prints the input dataset

- Outlier detection: plots the data with outliers highlighted

- Estimation: plots the clean data with an estimation of the trend

- Info: gives information on the used method.

Some statistics are calculated as follow:

- difference: the weight différence between the estimation on OK data on last and first day of measurement per animal

- ADG (g/d): the average daily gain expressed in g/day is the ratio between the above difference and the number of days in the period under analysis per animal

Points are labeled as follow:

- black: the data point is a good data (OK)

- purple: the data point is an outlier (KO)

- red: the data point is out-of-range (OOR)

7/ The user can then export a dataset and the plots in separate files by clicking on the export buttons.

This action may take a while, in particular for producing the individual plots file.

Credits:

isabelle.sanchez@inrae.fr - INRAE MISTEA - TechCare project - 2021-2023

bertrand.cloez@inrae.fr - INRAE MISTEA - TechCare project - 2021_2023

INRAE - UMR SELMET - UMR MISTEA

GPL-3 license - v1.1.0

To cite the kfino method, please use the following e-Print by Cloez B., Fontez B., González García E. and Sanchez I. (2022): arXiv:2208.00961.